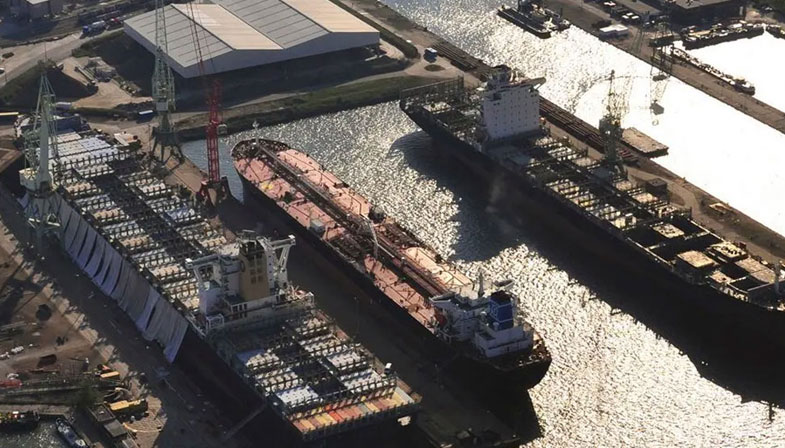

Shipyard

Locations

As leading ship marketing agents operating worldwide, we’re proud to connect you with only proven and capable international shipyards, giving you access to quality marine services that suit your ships’ schedules and requirements.

Cosco Shipping Heavy Industry Co., Ltd

Dalian, China

COSCO Shipping Heavy Industry Co., Ltd (CHI) is the shipping industry cluster of COSCO SHIPPING CORPORATION Group and has five major shipyards stretching across China, from Guangdong in the South to Dalian in the North.

Cosco Shipping Heavy Industry Co., Ltd

Nantong, China

COSCO Shipping Heavy Industry Co., Ltd (CHI) is the shipping industry cluster of COSCO SHIPPING CORPORATION Group and has five major shipyards stretching across China, from Guangdong in the South to Dalian in the North.

Cosco Shipping Heavy Industry Co., Ltd

Shanghai, China

COSCO Shipping Heavy Industry Co., Ltd (CHI) is the shipping industry cluster of COSCO SHIPPING CORPORATION Group and has five major shipyards stretching across China, from Guangdong in the South to Dalian in the North.

Cosco Shipping Heavy Industry Co., Ltd

Zhoushan, China

COSCO Shipping Heavy Industry Co., Ltd (CHI) is the shipping industry cluster of COSCO SHIPPING CORPORATION Group and has five major shipyards stretching across China, from Guangdong in the South to Dalian in the North.

Cosco Shipping Heavy Industry Co., Ltd

Guangdong, China

COSCO Shipping Heavy Industry Co., Ltd (CHI) is the shipping industry cluster of COSCO SHIPPING CORPORATION Group and has five major shipyards stretching across China, from Guangdong in the South to Dalian in the North.

Namibia Drydock & Ship Repair (NAMDOCK)

Walvis Bay, Namibia

Since its inception in 2006, NAMDOCK has established itself as a highly successful smart partnership between the Namibian government and the private sector.

Malaysia Marine Heavy Engineering

Jahor, Malaysia

Malaysia Marine and Heavy Engineering Holdings Berhad (MHB) is a globally trusted energy and marine solutions provider for a wide range of offshore and onshore facilities and vessels.

EDR Antwerp Shipyard

Antwerp, Belgium

A Full Service Shipyard in the Heart of Europe

Detyens Shipyard

South Carolina, USA (East Coast)

For more than 55 years Detyens shipyards has supported commercial ship owners, domestic and abroad, with an experienced team that emphasises quality safety and a competitive price.

Colombo Shipyard

Sri Lanka

An Odessey of Excellence. Sri Lanka’s Pioneer Shipbuilding and Ship Repairing Centre.

China United Drydocks

China

CUD (Weihai) Shipyard Co., LTD. it belongs to Shandong Xinhong Group Co., Ltd. was established in 2010.

Besiktas Shipyard

Yalova, Turkey

Besiktas Shipyard was established in 2007 in Yalova Turkey as an investment of Besiktas Group. Today it is listed as the 8th most active ship repair yard in the World, ranking 1st place in Europe with over 180 ships docking per annum.

ART Shipyard

Tuzla, Turkey

Art Shipyard was established in 2019 to offer a new generation of repair facility in the traditional repair hub of Tuzla.

Asyad Shipyard

Duqm, Oman

Asyad Drydock (formerly Oman Drydock Company), a member of Asyad Group, Oman’s global integrated logistics service provider was established in 2011.

Tallin Shipyard (BLTR)

Estonia

Located at the mouth of the Gulf of Finland, Tallin Shipyard has undergone continuous development and presents a clean and modern shipyard with all the required infrastructure for you project. The Yard has around 2300m of berth space with capacity for vessels up to 200m long.

Turku Repair Yard Ltd (BLTR)

Finland

With the one of the largest dry docks in Europe, Turkru Repair Yard has extensive experience in the sector and has the capability to undertake the most demanding repair projects.

Western Shiprepair (BLTR)

Klaipeda, Lithuania

Expanded in 2020 with two additional floating docks including the largest floating dock in the Baltic, Western Shiprepair has over 900m of berth space giving capacity to accept Aframax, Panamax and Post Panamax vessels.

Cammell Laird

Merseyside, UK

Cammell Laird has been at the forefront of UK shipbuilding and ship repair for more than 120 years.

WestSEA Viana Shipyard

Viana do Castelo, Portugal

Located at Viana do Castello, Northern Portugal, WestSEA Shipyard is an internationally renowned shipbuilding and repair facility at the centre of trade routes between North Europe, The Mediterranean and the Americas.

Keppel Subic shipyard

Philippines

Lorem ipsum dolor sit amet consectetur adipisicing elit. Enim ipsa ea nostrum eveniet at dignissimos veniam minima iusto molestias a repellat ratione, eum tempora, sed fugiat, consequuntur voluptatibus dicta ipsum?

Batangas Shipyard

Philippines

Lorem ipsum dolor sit amet consectetur adipisicing elit. Enim ipsa ea nostrum eveniet at dignissimos veniam minima iusto molestias a repellat ratione, eum tempora, sed fugiat, consequuntur voluptatibus dicta ipsum?

Keppel Tuas Shipyard

Philippines

Lorem ipsum dolor sit amet consectetur adipisicing elit. Enim ipsa ea nostrum eveniet at dignissimos veniam minima iusto molestias a repellat ratione, eum tempora, sed fugiat, consequuntur voluptatibus dicta ipsum?

Keppel Benoi

Singapore

Lorem ipsum dolor sit amet consectetur adipisicing elit. Enim ipsa ea nostrum eveniet at dignissimos veniam minima iusto molestias a repellat ratione, eum tempora, sed fugiat, consequuntur voluptatibus dicta ipsum?

Keppel Gul

Singapore

Lorem ipsum dolor sit amet consectetur adipisicing elit. Enim ipsa ea nostrum eveniet at dignissimos veniam minima iusto molestias a repellat ratione, eum tempora, sed fugiat, consequuntur voluptatibus dicta ipsum?

Orient Shipyard

South Korea

Orient Shipyard is the premier ship repair facility in South Korea with two yards located in Busan and nearby Gwangyang.

Park Shipyard

Yalova, Turkey

Can accommodate five vessels simultaneously, up to LR1 tankers, panamax bulk carriers and feeder container ships.

Xinya Shipyard

Zhoushan, China

Zhoushan Xinya Shipyard Co., Ltd. is located in Donglangzui of Liuheng Town, Zhoushan City, Zhejiang Province. It covers an area of more than 900 thousand square meters, with a construction area of 230 thousand square meters and coastline of about 3,600 meters.

Asaba Shipyard

Equatorial Guinea

ASTILLEROS DE GUINEA ECUATORIAL S.A. was founded in 2009 and located in the port of Malabo, Equatorial Guinea.

International Ship Repair

Tampa, USA

Located in Tampa, Florida; International Shiprepair and Marine Service Inc has been repairing vessels since 1973 and has become the leading ship repair facility in the Gulf region, conveniently located for vessels trading in U.S., Central, South America and the Caribbean regions.

Click on the location pins to reveal shipyard details.

Shipyard Locations

With exclusive representations in the UK of a first-class portfolio of facilities offering dry docking, repairs, conversions and modifications with specialist capabilities and capacity; we can support you through any size project worldwide ensuring timely and cost effective completion.

Want to know more?

We want to talk to you about Encompass Marine and how we can help your business.

Contact us View a full list of our shipyards below. Click on each one to reveal the shipyard details and capabilities.